What is glass aggregate plaster for facade?

ARCH DESIGNS

Advantages and benefits:

Glass aggregate plaster, when used for facades, serves not only as an aesthetic enhancement but also brings several functional benefits and advantages, particularly for building facades, which make it an appealing choice in both residential and commercial construction:

Aesthetic Versatility

The glass pieces within the plaster can be selected in various colors, sizes, and levels of transparency, providing architects and designers with a wide range of aesthetic options. This versatility allows for custom designs that can be tailored to enhance the architectural style of a building or to make a bold visual statement.

Environmental Sustainability

Using recycled glass in plaster contributes to environmental sustainability. It repurposes materials that would otherwise contribute to landfill waste and reduces the demand for virgin materials, thereby conserving natural resources.

Enhanced Durability

Glass aggregate plaster is more durable than traditional plaster because glass does not react chemically with the elements as some other aggregates might. This reduces the risk of degradation over time and leads to a longer lifespan of the building's exterior surface.

Reduced Maintenance

The durability of glass aggregate plaster translates into lower maintenance costs. It is less prone to cracking and degradation, which means it doesn’t need to be repaired or replaced as frequently as traditional plaster.

Energy Efficiency

The reflective properties of glass can help improve a building’s energy efficiency by reflecting sunlight and reducing heat absorption. This can keep buildings cooler in warmer climates, potentially lowering air conditioning costs and energy use.

Improved Light Dynamics

The reflective and translucent qualities of glass can create dynamic light effects on the facade of a building. As the sun moves, the appearance of the plaster can change, adding a lively and vibrant quality to the structure.

Sound Insulation:

Glass aggregate can enhance the sound insulation properties of a facade. The density and variability of the glass within the plaster can help block and absorb sound waves, making it suitable for buildings in noisy environments.

Cost-Effectiveness

While the initial cost might be higher than traditional plaster, the long-term savings from reduced maintenance and energy efficiency can make glass aggregate plaster a cost-effective choice over the life of a building.

Making Grooves Is Mandatory

Making Groove: Forming groove of uniform size in the top layer on rough plaster surface forAggregate Plaster / Grit Wash Plaster as per approved pattern using wooden battens/ aluminium channel, (includes in labour rate), nailed to the underlayer, including removal of wooden battens, repair to the edges of panels and finishing the groove complete as per specifications and direction of the Engineer-in-charge.

Mandatory: Making a groove of every 2-meter panel vertical or horizontal is mandatory. It acts as an expansion joint.

Thickness : 10 mm

Surface Preparation : Plaster Surface Requires

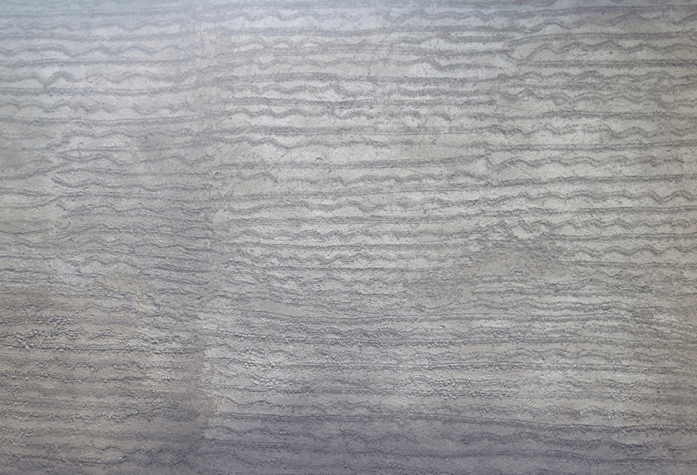

- For proper bonding the plaster should be rough. Marked by combing the surface with wavy lines using a wire brush or nail comb.

- The base should be hard and properly cured for a minimum of 5 to 6 days.

How Do You Clean Stone Crete Plaster?

Stone Crete Plaster is composed of a mix of elements: cement, coarse aggregate (usually crushed stone), fine marble powder, hardener and water. You can change the look of the finished plaster by making changes in the elements using white cement instead of Gray cement, for example, or using crushed colour glass in place of crushed stone. These choices can change the look of exposed aggregate concrete dramatically.

Special decorative aggregates frequently used for exposed Stone Crete Plaster and include a variety of decorative stones in many different colours. While Stone Crete Plaster finishers usually hide the aggregate with a smooth layer of cement paste, you can create aesthetically appealing looks by exposing the aggregate. Stone Crete Plaster is a 10 to 15 mm thick granular effect decorative texture.