Glass & Mirror Aggregate Plaster – Stylish Plaster Texture for Modern wall plaster design

What Is glass texture Aggregate Plaster? A Decorative & Sustainable Wall Plaster Design

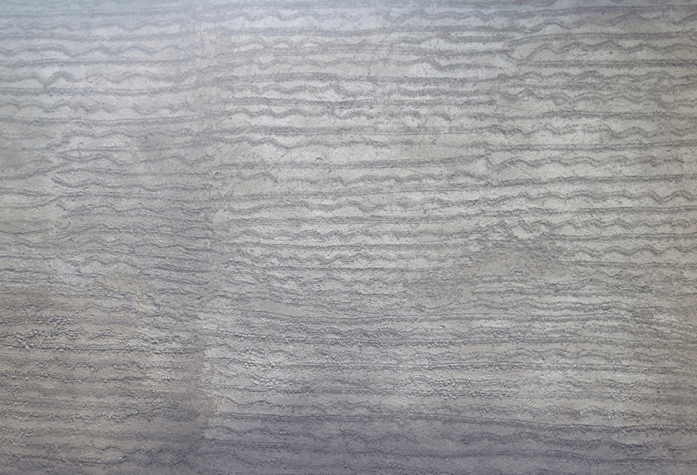

The wall plaster design using glass aggregate stands as a sustainable advancement that combines environmental importance with aesthetic beauty. Crushed glass and mirror fragments are used in this high-end binder-based rendering method to give indoor and outdoor walls a striking appearance. Modern interiors benefit from reflective glass as an excellent material choice which deepens surface appearance and enhances brightness. The product delivers both enhanced protection against weather conditions and extended longevity with an eye-catching mood. The material also operates under the name of grit plaster. Glass aggregate plaster works well for modern building interiors and exterior walls as well as facade applications because it delivers a sustainable resilient surface which adds a contemporary design element.

The application of glass aggregate plaster delivers both insulation advantages that control building temperatures. The material consists of recycled elements that serves as an environmentally-friendly choice suitable for sustainable modern architectural projects.

ARCH DESIGNS

Key Advantages of glass texture Aggregate Plaster for Modern Facades & Interiors

Glass aggregate plaster, when used for facades, interiors, and exterior wall designs, serves not only as an aesthetic enhancement but also offers several functional benefits. It is a preferred choice for both residential and commercial construction due to its durability, sustainability, and unique texture appeal.

Aesthetic Versatility

The glass texture within the plaster can be customized in various colors, sizes, and transparency levels, giving architects and designers flexibility in creating stunning wall plaster designs. Whether for modern exterior wall texture designs or bold interior decor, this plaster provides a sophisticated and vibrant finish.

Environmental Sustainability

Utilizing recycled glass in the plaster contributes to sustainable construction by reducing landfill waste and conserving natural resources. This makes glass aggregate plaster an eco-friendly choice for green building projects.

Enhanced Durability

Unlike traditional plaster, glass aggregate plaster is highly resistant to weathering, cracking, and chemical degradation. This makes it ideal for exterior walls, facades, and interior feature walls, ensuring long-term durability with minimal wear and tear.

Reduced Maintenance

With its hard, crack-resistant surface, glass aggregate plaster requires minimal maintenance. It retains its plaster texture without frequent repairs, making it a cost-effective solution for high-end architectural projects.

Energy Efficiency

The reflective properties of glass texture help in reducing heat absorption, keeping interiors cooler in warm climates. This can lead to lower energy costs by minimizing the need for air conditioning, making it an energy-efficient plaster texture option.

Improved Light Dynamics

The reflective and translucent glass particles interact with natural light, creating a dynamic and ever-changing visual effect on wall surfaces. This adds a luxurious and modern aesthetic to interior and exterior wall texture designs.

Sound Insulation:

The density and composition of glass aggregate help in absorbing sound waves, reducing noise pollution in busy urban environments. This makes it an ideal choice for commercial buildings, offices, and homes requiring enhanced acoustic insulation.

Cost-Effectiveness

Although the initial investment in glass aggregate plaster may be higher than traditional plaster, its long-term benefits, such as low maintenance, durability, and energy savings, make it a financially smart choice for modern construction projects.

Making Grooves Is Mandatory

Making Groove: Forming groove of uniform size in the top layer on rough plaster surface forAggregate Plaster / Grit Wash Plaster as per approved pattern using wooden battens/ aluminium channel, (includes in labour rate), nailed to the underlayer, including removal of wooden battens, repair to the edges of panels and finishing the groove complete as per specifications and direction of the Engineer-in-charge.

Mandatory: Making a groove of every 2-meter panel vertical or horizontal is mandatory. It acts as an expansion joint.

Thickness : 10 mm

Surface Preparation : Plaster Surface Requires

- For proper bonding the plaster should be rough. Marked by combing the surface with wavy lines using a wire brush or nail comb.

- The base should be hard and properly cured for a minimum of 5 to 6 days.

How Do You Clean Stone Crete Plaster?

A Stone Crete Plaster is a mixture of cement, fine marble powder, hardener, water, and grit plaster (crushed stone aggregates), a multipurpose wall plaster design. By altering these components, such as by substituting white cement for gray cement or adding broken colored glass for a distinctive glass texture look, the finished plaster texture can be personalized. These modifications make exposed aggregate concrete a more fashionable and long-lasting option.

Stone Crete Plaster frequently uses unique aggregates, such as colorful stones, for decorative finishes. Although a smooth layer of cement paste usually covers the aggregate, exposing it produces a textured and eye-catching look. When put in a layer that is 10 to 15 mm thick, this grit plaster provides both interior and external surfaces with long-lasting resilience and a sophisticated appearance.